Wrapping Machines

Wrapping Machines: The Unsung Heroes of Packaging Efficiency

In the fast-paced world of packaging, efficiency and convenience are key. That's where wrapping machines come into play. Whether you're packaging individual items or bundling multiple products together, these machines are designed to streamline the packaging process, saving you time and effort.

From food and beverage industries to manufacturing and e-commerce businesses, wrapping machines have become invaluable tools, ensuring that products are securely wrapped and protected during transit. With advanced features like adjustable settings for tension and speed, these machines offer flexibility to accommodate various packaging needs.

Not only do wrapping machines enhance productivity, but they also contribute to cost savings by reducing material waste. With their automated operation, they eliminate the need for manual intervention, minimizing the risk of human error and increasing consistency in packaging.

Investing in a wrapping machine can provide a significant competitive advantage, enabling you to meet the demands of a rapidly evolving market. So, whether you're a small business owner or a large-scale manufacturer, consider the benefits of incorporating a wrapping machine into your packaging process.

Types of Wrapping Machines

The realm of wrapping machines is diverse, with each type designed to fulfil a specific role in the packaging process. Stretch wrap machines, for instance, are used extensively in pallet wrapping. They typically employ a film that is stretched around products, ensuring stability and protection for goods during transportation.Shrink wrap machines, on the other hand, are ideal for creating a tight seal around an item. They utilise heat to shrink a plastic film around the product, providing a snug fit that is perfect for protecting individual items or combining smaller products into a single package.

There are also strapping machines, which are perfect for securing heavier loads with straps made of various materials, such as plastic or steel. These machines ensure that bulky or heavy items remain tightly bound, reducing the risk of damage when goods are on the move.

Benefits of Using Wrapping Machines

The advantages of incorporating wrapping machines into your operations are numerous. First and foremost, they significantly increase the speed of the packaging process. Automated wrapping can be up to five times faster than manual methods, which means that businesses can handle higher volumes of product with the same amount of labour.These machines also improve the consistency and quality of packaging. Every item is wrapped in the same manner, ensuring that each product meets the same standard of protection. This uniformity is crucial for maintaining brand integrity and customer satisfaction.

Moreover, wrapping machines are adept at reducing waste. They use precisely the right amount of wrapping material needed, cutting down on excess and promoting a more sustainable approach to packaging. This not only helps the environment but also reduces costs associated with materials.

Factors to Consider When Choosing a Wrapping Machine

Selecting the appropriate wrapping machine for your business requires careful consideration of several factors. The size and type of products you are wrapping will heavily influence the kind of machine you need. For instance, smaller items might benefit from a shrink wrap machine, while larger, palletised goods might necessitate a stretch wrap machine.Another critical aspect is the capacity of the machine. It's essential to choose a machine that can keep up with your production demands. This includes considering the speed of the machine and whether it can sustain continuous operation over long periods.

The level of automation is also a key decision point. Fully automated machines provide the highest efficiency but come at a higher cost and require a more significant initial investment. Semi-automated models might be more appropriate for smaller operations or businesses with lower volumes of packaging.

How to Operate a Wrapping Machine

Operating a wrapping machine is typically straightforward, but it does require some training and understanding of the machinery. Initially, you must select the appropriate settings for the specific product you're wrapping, which includes adjusting the tension, speed, and, if applicable, the heat setting.Once the machine is set up, the product is placed in the designated area, and the wrapping process is initiated either manually or via an automated system. For pallet wrappers, the pallet is placed onto the turntable, and the machine then applies the stretch film as the pallet rotates.

After the wrapping cycle is complete, the machine will typically cut the wrapping material and seal the end. The product is then ready to be removed from the machine and moved to the next stage of the distribution process.

Common Troubleshooting Issues with Wrapping Machines

Even the most reliable wrapping machines can encounter issues from time to time. One common problem is the film not adhering properly to the products, which could be due to incorrect tension settings or an issue with the film itself.Another frequent concern is inconsistent wrapping, where products are not being wrapped uniformly. This can often be rectified by recalibrating the machine's settings or conducting routine maintenance to ensure all components are functioning optimally.

Machine jams are also a possibility, particularly if the wrapping material becomes entangled in the machinery. Regular cleaning and inspection can help to prevent such occurrences and ensure the smooth operation of the wrapping machine.

Maintenance Tips for Wrapping Machines

To ensure the longevity and efficient operation of your wrapping machine, regular maintenance is essential. This includes cleaning the machine after each use to prevent the build-up of debris that can cause malfunctions.Lubrication of moving parts is also crucial. This helps to reduce friction and wear, extending the life of the machine. Always use the recommended type of lubricant and adhere to the manufacturer's guidelines regarding maintenance schedules.

It's also wise to conduct periodic inspections of the machine's components. Check for signs of wear and tear, and replace any parts that are damaged or nearing the end of their service life. This proactive approach to maintenance can prevent unexpected breakdowns and costly downtime.

Latest Advancements in Wrapping Machine Technology

The packaging industry is continually evolving, and wrapping machine technology is advancing accordingly. Modern machines now come equipped with sophisticated sensors and control systems that can automatically adjust settings in real time for optimal wrapping.Another significant development is the introduction of eco-friendly machines that use biodegradable or recyclable materials. These advancements demonstrate a commitment to sustainability while still providing the high levels of protection required for shipping and handling.

Additionally, the integration of IoT (Internet of Things) technology means that wrapping machines can now be monitored and controlled remotely. This allows for greater flexibility in the management of packaging operations and can lead to improved efficiency and productivity.

Popular Brands of Wrapping Machines

Several brands are renowned for producing high-quality wrapping machines. Companies like Lantech and Signode have established reputations for reliability and performance in the stretch wrapping sector.Shrink wrapping is similarly dominated by trusted brands such as Shanklin and Sealed Air, both of which offer a range of machines catering to different sizes and types of products.

In the strapping machine market, brands like Strapack and Mosca stand out for their durable and efficient machinery. These manufacturers have honed their offerings to ensure that their machines meet the exacting demands of modern packaging operations.

Conclusion: The Importance of Using Wrapping Machines in Various Industries

The use of wrapping machines is now considered essential across a broad spectrum of industries. They provide not just the obvious benefits of speed and efficiency but also contribute to improved safety, sustainability, and cost-effectiveness.Businesses that invest in quality wrapping machines can expect to see a return in the form of reduced labour costs, minimal product damage, and enhanced customer satisfaction due to the consistent delivery of well-packaged goods.

In conclusion, wrapping machines are more than just tools for packaging; they are integral components of a modern, efficient, and competitive business model. As technology continues to advance, these machines will undoubtedly play an even more critical role in the packaging industry's future.

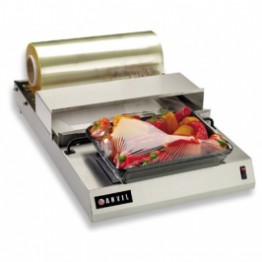

Gatto Wrapping Machine 500mm

Gatto Wrapping Machine 500mmPower: KW 0.21Weight: KG 7Dimension: MM 670X550X140• Stainless steel 500..

R2,028.00 R2,142.86 Ex Tax: R2,028.00

Wrapping Machine 380mm Global/Gatto

Wrapping Machine 380mmPower: KW 1.75Weight: KG 6Dimension: MM 670X430X140• Stainless steel 380mm• Se..

R2,513.00 R3,590.00 Ex Tax: R2,513.00

Wrapping Machine S/Steel Anvil - 380mm.

Wrapping Machine S/Steel - 380Mm.. Utilized In Any Business For Wrapping Of Vegetables, Fruit, Meats..

R1,877.65 R2,503.53 Ex Tax: R1,877.65

Wrapping Machine S/Steel Anvil - 500mm

Wrapping Machine S/Steel - 500Mm. Utilized In Any Business For Wrapping Of Vegetables, Fruit, Meats,..

R2,094.12 R2,792.16 Ex Tax: R2,094.12

Showing 1 to 4 of 4 (1 Pages)